- Home

- Logifleet Blog

- How to keep track of your fleet's maintenance requirements

How to keep track of your fleet's maintenance requirements

Healthy vehicles and machines are a sign of a healthy business. When you take good care of your most valuable investments, they will generate more ROI for your company. The best way to get the most out of your top assets is to adopt a proactive fleet maintenance program.

Fleet maintenance is the act of scheduling and performing routine vehicle service work. This ensures your vehicles are always in safe operating condition. Fleet maintenance involves training drivers to do daily inspections, following a regular service schedule and using GPS tracking software to manage your fleet.

In this blog post we will discuss why it is important to stay on top of fleet maintenance. We'll also show you how fleet management systems work and the features you need to keep your operations running smoothly around the clock.

Why Is It Important to Monitor Your Fleet's Maintenance

Here are the top three reasons why fleet maintenance should always be a fleet manager’s number one priority.

1. Safety First

Vehicle malfunctions such as brake failures can lead to accidents, injuries or fatalities. For commercial fleets, the annual accident rate is as high as 20% due to the number of kilometers driven each year (Source: Automotive Fleet).

Fleet managers have a moral and legal obligation to do their best to protect their drivers and operators from bodily harm. For example, in Switzerland, construction fleets must comply with OPair (a Swiss law) and prove that machines for machines with a power equal to or greater than 18 kW are equipped with a particulate filtration system. Managers also need to show documentation for the maintenance of the antipollution system, antipollution sticker, and more.

Rare but potentially severe accidents may result in lawsuits, bad PR, increased insurance costs, and a ripple of unintended consequences. Small fleets could be one bad accident away from bankruptcy.

If you don't maintain your fleet of vehicles and machines, they could break down at any time and become stranded on a job site or in traffic. This causes delays to job sites, missed deadlines for clients, and increased operational expenses. Not to mention it's an inconvenience to the driver too. In short, roadside breakdowns will cost you more than just the price of repairs.

2. Extend Your Vehicle Health and Lifespan

Staying on top of vehicle maintenance extends your asset's health and lifespan. If you maintain your fleet vehicles, they will be more reliable which means you'll spend less time and resources fixing them. Maintenance also reduces a vehicle's total cost of ownership, which helps reduce your overall fleet costs. Lastly, you'll also earn more reselling well-maintained vehicles.

3. Increasing Your Bottom Line

The final reason why it's so important for fleet managers to stay on top of their fleet’s maintenance schedules: saving money! When preventive services are completed regularly, repairs become more infrequent, which means reduced vehicle costs over time. By automating the maintenance process, you can eliminate extra administrative work, which means mechanics and equipment managers spend more time actually making repairs, not filling out forms. With fleet management software, you can also better coordinate mechanics’ time so they can be more productive at each job site and service multiple pieces of equipment at once instead of making multiple back and forth trips. This means you pay less for labor and get more tasks done, faster.

Did you know? Scheduled preventative maintenance reduces maintenance-related downtime by up to 20% (Source: Automotive Fleet)

Sometimes, you may not even realize why a vehicle is underperforming or why your fleet costs are rising.

For example, gearbox problems may not seem like much on their own but they can cause additional wear due to unnecessary upshifting/downshifting. This leads to increased engine load. A higher engine load results in increased fuel consumption, which in turn leads to decreased fleet efficiency.

Poorly tuned engines, cluttered truck beds, clogged air filters, and unde-inflated tires can also reduce mileage and hurt your vehicle’s performance.

Worse, neglected vehicles also cause more environmental damage. Engine misfires, for example, waste fuel and emit harmful exhaust emissions.

Staying on top of maintenance increases fleet efficiency. Less downtime means more money in your pocket! It’s also crucial for protecting the health and safety of your workers and drivers.

Tracking vehicle maintenance will help you maintain compliance with local regulations and laws that require periodic inspections or routine services. Vehicle manufacturers may also require regular maintenance to stay within the warranty.

In conclusion, staying up-to-date with your fleet's maintenance is critical because it increases safety, improves vehicle longevity, and reduces fleet costs. Interested in reading more cost-saving tips? Check out our blog on how to reduce fleet costs.

How Fleet Maintenance Systems Work

First off, what is a fleet management system? It's a comprehensive software solution that helps fleet managers make better decisions, faster.

Software like Logifleet can send alerts for upcoming or overdue service requirements and inspections. These notifications are pushed to your mobile or desktop app. No more scribbled calendar reminders or sticky notes on your desk! Logifleet can also track work orders, inventory, driver schedules, and more. Use our automatically updated logbook to see the number of kilometers for each vehicle and how many hours an engine has been running vs. idling.

Logifleet Software Features

Here are just some of the many powerful Logifleet features that will transform the way you run your fleet.

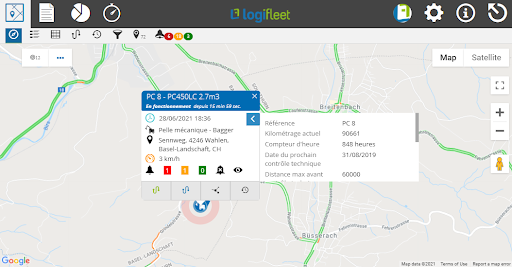

Screenshot: Example of a maintenance notification for a construction machine. Managers can see the current KM, engine hours, and date of the next maintenance check. Get notified via a pop-up, in list format, in a maintenance report, or by email.

Screenshot: Example of a maintenance notification for a construction machine. Managers can see the current KM, engine hours, and date of the next maintenance check. Get notified via a pop-up, in list format, in a maintenance report, or by email.

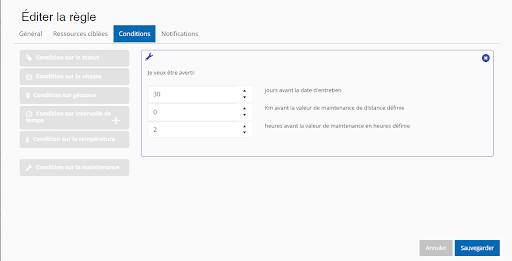

Screenshot: How to set up automatic maintenance reminders for a vehicle

Asset Management

Logifleet makes it easy to organize and categorize all your most valuable assets. Our software can track vehicles, tools, and heavy machinery. The asset management system logs a variety of important data such as:

✔️ Asset location and activity

✔️ Service history and maintenance schedules

✔️ Downtime and idling time

✔️ Fuel usage and mileage

✔️ Historical usage trends and routes

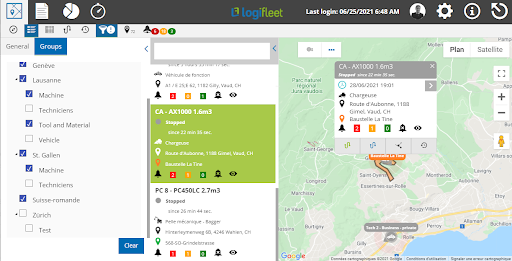

Screenshot: Organize objects by groups, subgroups, by type to find them easily

Screenshot: Organize objects by groups, subgroups, by type to find them easily

Equipped with this data, fleet managers will see which assets are being overused, underused, or misused. This can help them make better decisions about maintenance, repairs, replacements, and driver training.

Maintenance Notifications

Service records for all your vehicles, tools, heavy equipment, and machines are all stored in one place for easy access. The system will automatically notify managers about upcoming or overdue inspections and maintenance dates.

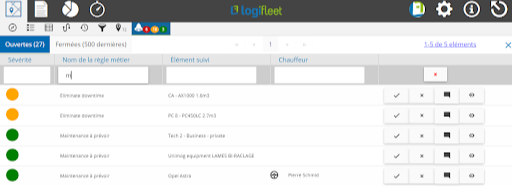

Screenshot: Alarms and notifications can be viewed, analyzed, commented on, and closed in the application. Alarm history is kept

Screenshot: Alarms and notifications can be viewed, analyzed, commented on, and closed in the application. Alarm history is kept

Easy Scheduling and Time Tracking App

Keep track of worker schedules, behavior, and attendance to better evaluate their performance. Worker Connect allows employees to track their hours through the mobile app.

Logifleet can help you reduce labor costs by allocating resources faster. If you perform maintenance and repairs in-house, this tool allows you to coordinate schedules to minimize vehicle downtime. Learn more about fleet scheduling here.

In-Depth Reports

Get real-time or historical data in just a few clicks. Logifleet’s robust reporting system gives managers increased visibility into all facets of their operations. Easily export, download and share the report with other team members.

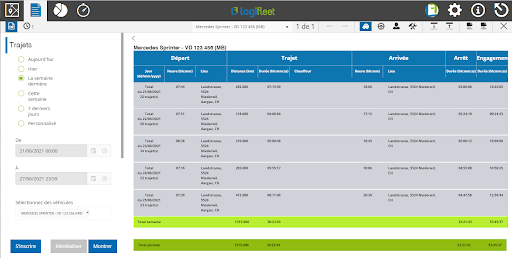

Screenshot: Weekly activity report for a vehicle or a driver

Screenshot: Weekly activity report for a vehicle or a driver

In addition to maintenance tracking, Logifleet also monitors driver and vehicle activities, inventory data, fuel usage, and more in real-time. Learn more fleet monitoring tips here.

Ready to transform your fleet and start saving money? Book an obligation-free demo call today.

Sources:

https://www.automotive-fleet.com/303123/fleet-safety-metrics-reverse-negatively-accidents-increase

https://www.automotive-fleet.com/341694/managing-the-cost-of-unscheduled-vehicle-downtime

En Budron H9

CH-1052 Le Mont s / Lausanne

T +41 21 651 06 51

Merkurstrasse 25

CH-8400 Winterthur

T +41 71 277 52 47