- Home

- Logifleet Blog

- 9 Metrics Every Fleet Manager Should Be Tracking To Optimize Efficiency

9 Metrics Every Fleet Manager Should Be Tracking To Optimize Efficiency

Ensuring your fleet is running smoothly and efficiently can be a challenge even for the most experienced fleet managers. There are many moving parts to keep track of, and it can be difficult to decide which metrics are the most important to focus on.

Turning to the fleet reporting tools is a great place to start. But, if you're not sure which data you should focus on and which key performance indicators (KPIs) you should track, it will be challenging to make informed decisions that will optimize your fleet's performance. After all, you can only improve what you measure.

To help you out, we've compiled a list of the 9 fleet metrics that every fleet manager should be tracking to ensure efficiency.

Total cost of ownership (TCO)

One of the most important fleet metrics to track is your fleet's total cost of ownership (TCO). TCO considers all the costs associated with running your fleet, including purchase price, depreciation, fuel, maintenance, and repairs.

To calculate TCO, you'll first need to total up all your fleet's operating expenses for a specific period. Once you have that number, you can divide it by the number of vehicles in your fleet to get its average TCO.

Tracking your fleet's TCO will give you a good idea of how much it costs to operate your fleet on a per-vehicle basis. This information can be helpful when making decisions about fleet expansion or fleet replacement.

Using your fleet's data, a good fleet management software can calculate fleet TCO for you. This can be a valuable time-saver, and it will help ensure your TCO calculations are accurate.

Equipment use

Another important metric for fleet managers to track is equipment use or asset utilization. Investing in your fleet isn't cheap, so you should ensure your fleet is being used as much as possible.

There are a few different ways to calculate equipment use. One way is to take the number of hours that your fleet was in use during a specific period. Divide it by the total number of hours that your fleet could have been in use.

For example, let's say your fleet was in use for 8,760 hours in a year (24 hours a day, 365 days a year). If your fleet's capacity is 10,000 hours, your fleet's equipment use, in this case, would be 87.6%.

Another way to calculate equipment use is to consider the number of miles your fleet traveled during a specific period. Divide it by the total number of miles your fleet could have traveled, and you'll get your equipment use percentage.

For example, if your fleet traveled 100,000 miles in a year, and it could have traveled a total of 120,000 miles, your fleet's equipment use would be 83.3%.

Equipment or construction machine use is essential to track because it can help fleet managers to identify areas where they can improve utilization. For example, if you notice that one of your vehicles or machines is only being used for a few hours each week, you might want to consider renting it out or selling it.

Preventive maintenance

Keeping track of preventive maintenance is a must if you want to avoid expensive repairs down the road, especially if we’re talking about construction machines. This metric measures the percentage of fleet vehicles that are up-to-date on their scheduled check-ups.

For example, an engine failure on a Liebherr R 926 excavator can cause approx. 48,000 CHF in repair costs. On the other hand, the average cost of preventive maintenance is between 3,500 and 3,700 CHF a year.

To track preventive maintenance, you should start by establishing a schedule for each vehicle in your fleet. Base that plan on the manufacturer's recommendations and the specific needs of each vehicle.

Once you establish a schedule, you can use fleet management software to track when each vehicle is due for service. This will ensure you don't miss a scheduled service, and all vehicles in your fleet will stay in good working condition.

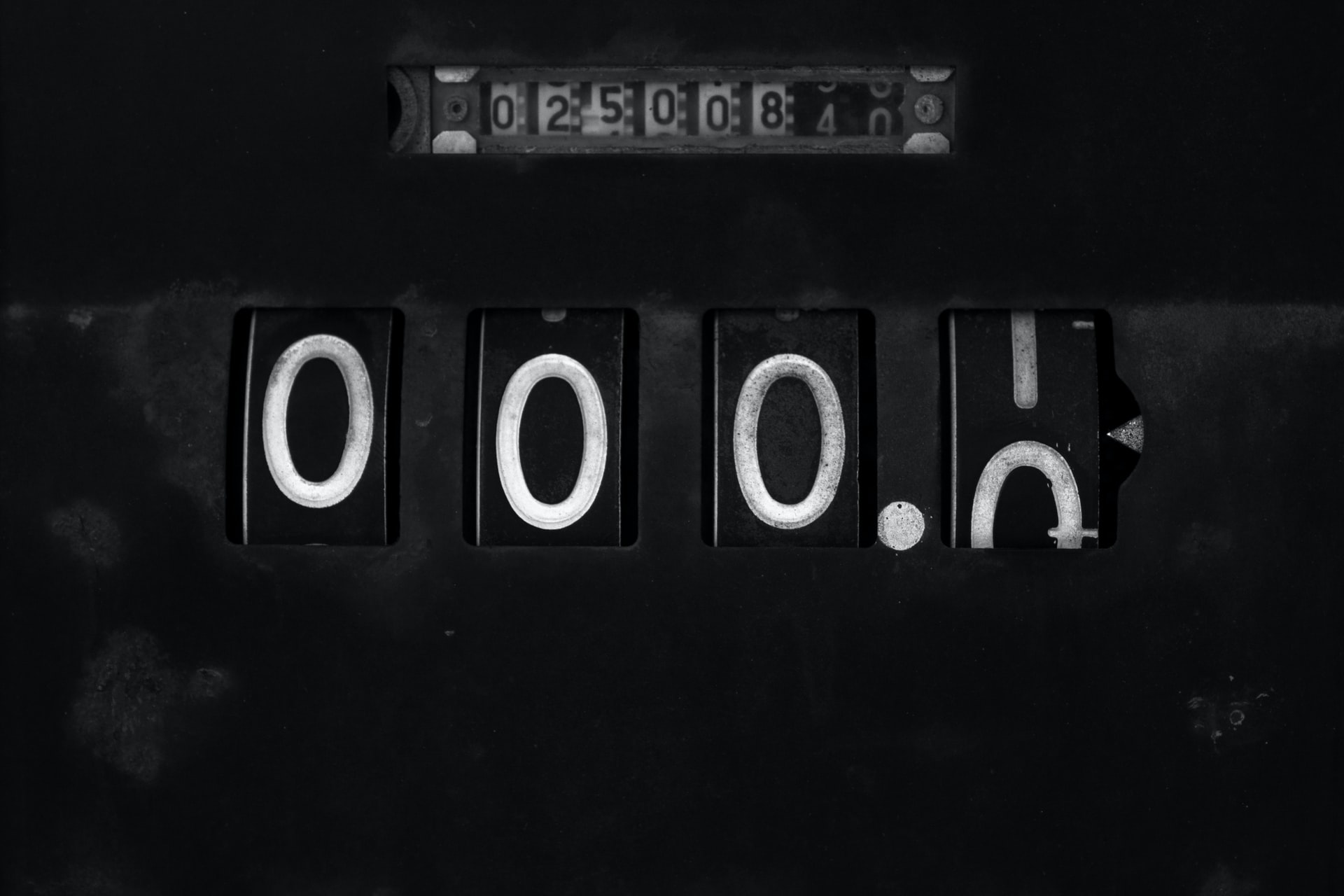

Odometer or orometer readings

Odometer readings give you valuable insight into how much wear and tear your fleet vehicles are experiencing. Orometer readings, on the other hand, will show you how long your machine engine was running. Tracking this can help you decide when to replace or trade machines or fleet vehicles.

To track odometer or orometer readings, you'll need to take manual readings and enter them into fleet management software. Luckily, some fleet management systems such as Logifleet come with GPS tracking devices that automatically record those readings. This won't just save you a lot of time; it will also ensure your readings are always accurate.

Driver behavior

Driver behavior is one of the most important fleet metrics to track. It measures how safe and efficient your fleet's drivers are, and it includes things like hard braking, sharp turning, rapid acceleration, idling, and speeding.

To calculate it, you'll need to track the number of accidents, traffic violations, and near-misses that each driver in your fleet was involved in. Dividing this number by the total number of miles driven, you will get the driver behavior rate.

Monitoring and identifying practices that can harm the driver and vehicle is critical in maintaining a safe fleet operation. Not to mention, diver behavior has a huge impact on the costs such as maintenance and fuel usage. Fortunately, you don't have to record and measure it by hand, as good fleet management software takes care of it using data from GPS tracking devices.

Fuel consumption

Fuel is one of the most significant fleet expenses, especially in the current economy, so it's essential to track its consumption to ensure you're not overspending. Measuring fuel consumption by hand is a poor use of time, as it can be both inaccurate and time-consuming. Instead, use fleet management software that integrates with GPS tracking devices to track fuel consumption automatically.

To get started, you can set up a fuel card for each fleet vehicle. Whenever a driver purchases fuel, they'll need to use the fleet fuel card. The fleet management software will then automatically track and record the purchase. Unfortunately, many companies already use employee fuel cards, but the data on it is often missing or incorrect, which is another thing a good fleet management software can help you with.

Once you have all your fuel consumption data, you can start looking for ways to reduce it. For example, you might want to consider implementing a fleet-wide fuel-saving policy or investing in more fuel-efficient vehicles.

Vehicle replacement

If your vehicle stays in operation longer than it should, it can cause asset performance to decline and operating costs to rise. That's why it's crucial to track the vehicle replacement metric.

To calculate it, you'll need to take into account the average lifespan of fleet vehicles and their depreciation rates. This information will help you determine when to replace each fleet vehicle. It will also help you budget for fleet replacements and ensure you're not spending too much on new vehicles.

Like most other fleet metrics, you can track this information manually, but fleet management software makes it much easier. With software like Logifleet, you can set up alerts that notify you when a fleet vehicle is due for replacement.![]()

Time tracking and delays

Another metric fleet managers should keep an eye on is time tracking and delays. This metric measures how much time fleet vehicles spend on the road and how often they experience delays due to traffic, weather, or other factors. It can also measure how many hours certain machines are in use.

To calculate it, you'll need to track the number of hours each fleet vehicle spends on the road and the number of delays it experiences. Dividing these two numbers will give you the time tracking and delay rate.

Accurate time tracking can help you optimize fleet routes and ensure your fleet vehicles are used efficiently. It can also help you identify fleet vehicles that frequently experience delays or machines that remain unused on the construction sites, and figure out why that is happening.

Fleet management software can make it easier to keep track of time tracking, delays and unused assets such as machines and equipment. With Logifleet, for example, you can see how long each fleet vehicle spends on the road and how often it experiences delays. You can also use the software to optimize fleet routes and ensure fleet vehicles are being used efficiently.

Performance metrics

So far, we've mentioned a variety of fleet metrics essential for a well-managed fleet. It's important to compile them to measure overall fleet performance. By looking at real-time and historical data, you can identify fleet performance trends and take steps to address them.

Pay attention to overall productivity, fuel efficiency, fleet utilization, and fleet downtime. All these factors play a role in the fleet performance and equipment downtime and need to be monitored closely. By compiling all the essential metrics in one place, fleet management software can make it easier to track fleet performance and identify issues early on.

Of course, fleet performance is only as good as the fleet manager. At the end of the day, it's up to you to make sure your fleet is running smoothly and efficiently.

How to use fleet data to improve fleet operations and performance

Now that you know which fleet metrics to track, it's time to put that knowledge into practice. The first step is, as you've probably guessed, to start using fleet management software to collect data. This will be essential for tracking mixed fleet performance and making improvements.

Once you have all the necessary data, you can start looking for ways to improve your fleet's operations. Here are a few ways you can do that:

- Analyze fleet data regularly to identify areas for improvement

- Compare fleet performance data with industry benchmarks

- Optimize routes to reduce fleet and machine downtime and fuel consumption

- Monitor driver performance and address any issues

- Invest in fuel-efficient fleet vehicles to improve fuel efficiency

- Monitor fleet utilization and make changes as needed

These are just some of the ways you can use fleet data to improve fleet performance. Of course, you'll need to tailor your approach to your fleet's specific needs. But with the right fleet management software in place, you'll have all the data you need to make improvements. And with a bit of effort, you'll be well on your way to running a more efficient and effective fleet.

The importance of reporting in fleet management

Fleet management tools can do a lot to improve fleet performance. But ultimately, we all know it takes more than purchasing software to make sure the fleet is running smoothly.

That's where fleet reporting comes in.

First, it allows you to track progress over time. This is important for identifying fleet performance trends and making improvements. Second, it gives you the data you need to make decisions about fleet operations. Finally, fleet reporting can help you hold employees accountable for their performance. Without timely and accurate reports, fleet managers would be flying blind and would likely make a lot of avoidable mistakes.

If you're not already doing so, we recommend that you start tracking and reporting on the metrics we've listed above. Doing so will help you optimize your fleet and improve your bottom line.

Conclusion

There are a variety of fleet management systems available on the market. However, not all of them are created equal. Some are very basic and only track a few of the metrics we've listed above. Others are much more extensive and track a wide variety of metrics.

When choosing a fleet management system, consider choosing one that is comprehensive and easy to use. Logifleet's fleet management solution is an excellent option for fleet managers looking for a user-friendly tool that makes it easy to track and report on all of the metrics we've listed above.

Using some of Logifleet’s solutions - Vehicle Connect Machine Connect, or Tool Connect, you can track your machines, vehicles, and equipment. That will give you instant access to driver logs and maintenance files, and enable you to track all assets and run analytics that will help you reduce costs.

To learn more about Logifleet's fleet management software, visit our website or contact us today. We'll be happy to answer any questions you have and provide you with a free demo of our software.

En Budron H9

CH-1052 Le Mont s / Lausanne

T +41 21 651 06 51

Merkurstrasse 25

CH-8400 Winterthur

T +41 71 277 52 47